Jump rope’s material discrimination and durability test

- Roger Yao

- Feb 24, 2022

- 4 min read

Updated: Mar 17, 2022

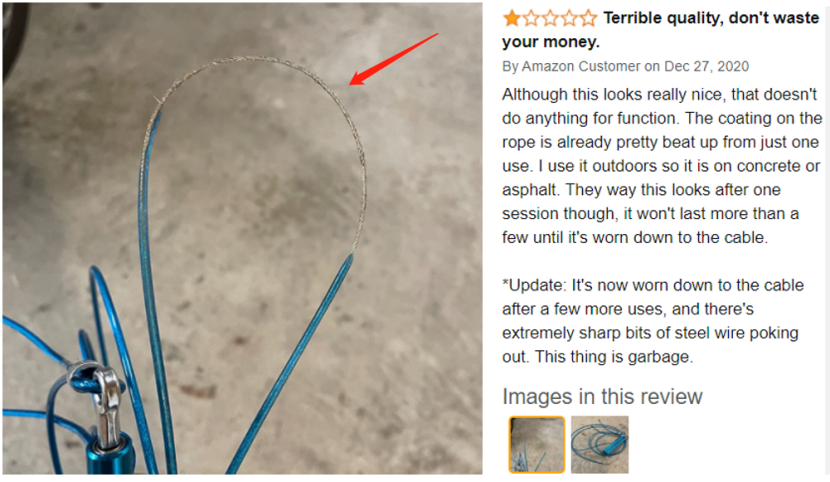

Some users complained that the speed rope was not durable, and some of poor-quality ropes broke after just one or two weeks of use. When the outer skin (plastic coating) of cable is damaged, the inner steel wire will soon break. (Refer to the negative comments on Amazon customers review)

So, the question is about how to make durable speed jump rope?

Before talking about the durability of speed jump rope, let’s firstly see how the rope is used?

Guinness world Record for fastest rope jumpers in 2017: Cen Xiaolin made 226 jumps in 30 seconds, or 7.5 jumps per second, breaking his previous record of 222 jumps, becoming the fastest jumper in the world.

There are many kinds of rope skipping, one of which is racing rope skipping also called high speed rope skipping or wire rope skipping. Many middle and advanced players who like to challenge speed will choose wire racing rope skipping. Anyway, such high-speed jump rope wear much more easily than the normal jump rope.

A rope for racing rope jumping

Steel rope skipping is very thin, usually with a diameter of 2.5mm or 3.0mm, 2.5mm is a common type in the market.

because of the small cross section, thin rope skipping could effectively reduce wind resistance, increase the speed of rotation. But too thin jump rope is relatively light-weighted, therefore, it is easily swaying in the wind. In order to get a little more weight, steel wire is used as the inner core, and plastic skin is covered on the outside.

In general, the part of the speed jump rope is made up of wire rope inside and plastic skin by coating outside. The plastic skin is the part that directly touches the ground and creates friction during jumping. The life of speed skipping rope mainly depends on the plastic coating outside.

Which material of plastic coating for jump rope is better?

Three commonly used materials of plastic coating for speed jump rope are PVC, PU and nylon. The consensus in market is that PU material has better life resistance among these three materials.

I asked one of speed jump rope manufacturers: how do you proof the PU is the best one, and what is the quantitative data to verify it? Are there standard and test comparison data reports for comparison?

However, the manufacturer did not give a specific and satisfied answer for that.

How to distinguish the material between PVC and PU?

In order to understand better the material, I decided to study it in my ways. However, I don’t have Nylon cable on hand, so I just take PVC and PU cable for testing and comparison.

From the appearance, they look the same and cannot easily tell the difference of the material.

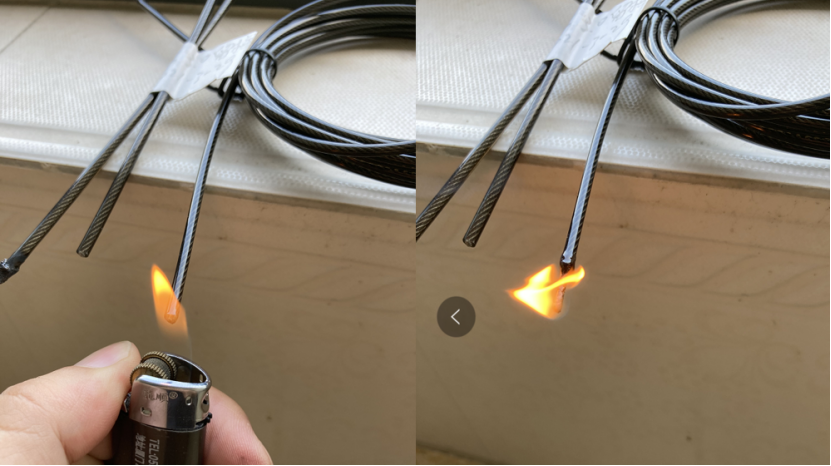

However, here is a quick and easy way to tell: burning

When I burn these two materials, the flame on PVC material is relatively bigger than that on PU, but not too much.

The burning speed of PU is faster, and we will see the liquid drip down after melting while PVC material has no liquid drip during burning.

After burning, PU material has been burned completely and the steel wire can be seen while the PVC material has residual attached to the steel wire, peel it by hand and ashes fall down.

Anyway, this is a quick and simple method to distinguish the PVC and PU material but not rigorous testing standard. Even the same type of material, the combustion phenomenon will vary because of formula, process and other factors.

Design of wear resistance test scheme

The wear resistance is the key point for jump rope life performance. However, after consulting with some companies in jump rope industry, there is no wear resistance test specifically for jump rope.

Then I decided to design one workable but simple test method.

After talking to friends, one of them suggested to develop one rocker mechanism to simulate the circle rotation of jump rope during using, and during rotation the jump rope hits the ground with designed roughness floor, then to see the wearing result under testing condition. However, this mechanism seems a little complicated to carry out.

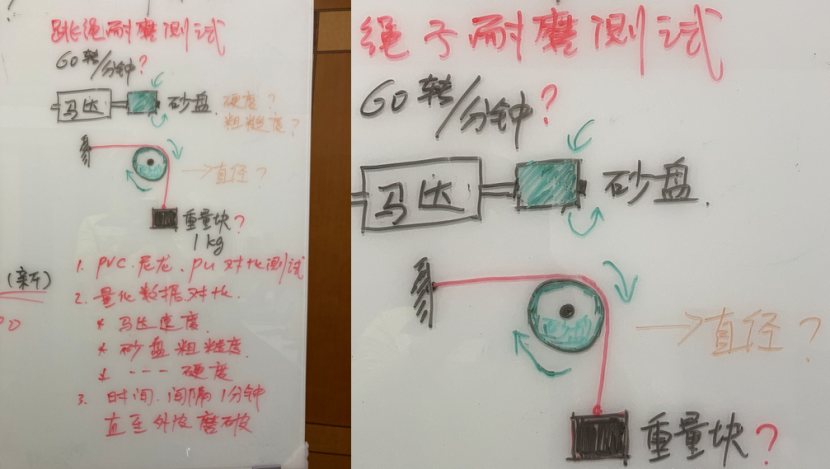

Another test scheme we proposed seems much easier to be done. See photo below.

The rope is pressed to a sand surfaced spindle with a weight block, and the sand spindle is driven to rotate by a low-speed motor to rub the rope surface. Set variable parameters such as time, speed, spindle roughness and hardness until the skin wears and exposes the metal wire part. This can be used to test the rope from different manufacturers, materials, specifications and get a comparative test result.

Anyway, the implementation of this test scheme was postponed because our jump rope project has stopped. One owner of jump rope manufacturer decided to build up such test device according to my proposal, he said, by doing this, it is a practical way to control the cable as incoming material, from the other side, it is a good proof to show the quantative test to customers, instead of just making quality guarantee by talking groundlessly.

Author:

Roger YAO (cs01@fitqs.com)

The founder of FITQS/FQC, providing quality inspection & product development service.

20-year experience in fitness/sporting goods industry for sourcing quality management.

The columnist of magazine “China Fitness Equipment” for product quality evaluation section.

Comments